The Impact of CNC Machines on Modern Manufacturing

Technology is rapidly changing every aspect of the modern world. One area that has been significantly impacted is the manufacturing industry. There has been a significant improvement in the entire manufacturing process since the introduction of Computer Numerical Control (CNC) machines.

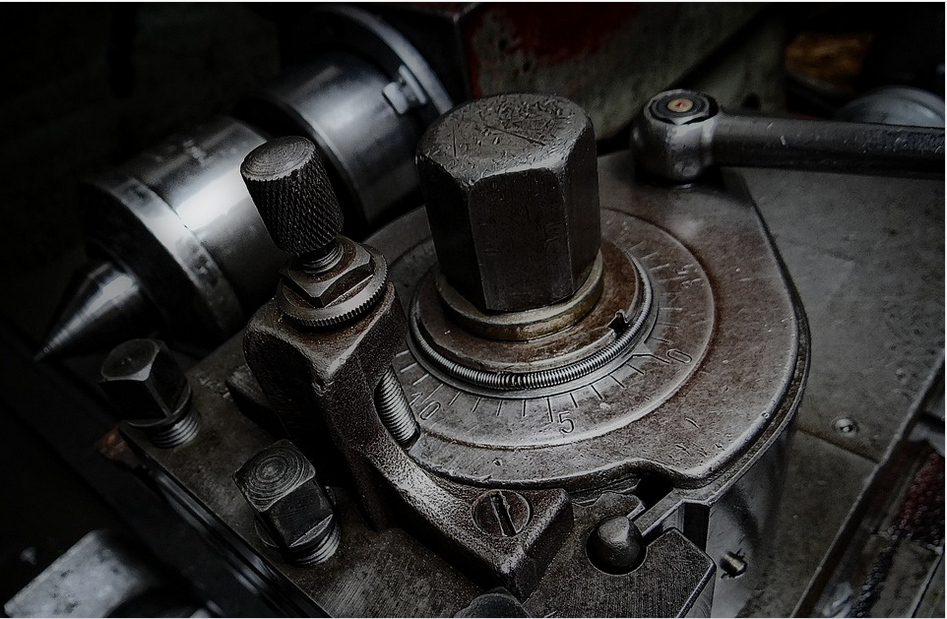

CNC machines first became operational in l940s and 50s, and ever since, the manufacturing industries have been experiencing steady growth. Their prototype parts are designed with the help of a computer. You can hire experts in CNC Lathe Services for the most efficient prototype parts for your machines. CNC machines are computer-controlled hence the entire manufacturing is automated.

Here are some of the ways CNC machines have impacted modern manufacturing:

Quicker Production

In modern manufacturing, if you do not enhance your production speed, the competition will trample you. CNC machines are automated and can run for an entire week, saving a lot of staff-hours. Since the devices are computer-controlled, you issue a command, and the manufacturing process starts without any manual input. The machines do not take breaks nor day-offs hence enhancing the manufacturing efficiency.

Allows Prototyping of Parts

Creating a product or mass production of a new product requires prototypes. Once you have CNC machines installed, you do not need new devices to start producing a new product. You design new prototype parts for the specific product you want to manufacture.

Creating a product or mass production of a new product requires prototypes. Once you have CNC machines installed, you do not need new devices to start producing a new product. You design new prototype parts for the specific product you want to manufacture.

Prototypes are computer-aided. You make small adjustments to your design, issue a command in using your computer, and you are good to go. You do not have to buy separate parts for the manufacturing as everything is already encompassed in the machines. This means that you can mass-produce a new product at a relatively low cost.

Requires Minimum Supervision

CNC machines require little monitoring. Everything is computer-controlled, and they can run for a long time when they have been programmed to do so. These machines operate on their own except for the occasional replacement of a few tools.

CNC machines require little monitoring. Everything is computer-controlled, and they can run for a long time when they have been programmed to do so. These machines operate on their own except for the occasional replacement of a few tools.

Reduces Material Wastage

Using traditional manufacturing methods leads to lots of wastes in materials. Human workers are not as perfect as machines, and sometimes they make mistakes. When mistakes are made, raw materials are destroyed, which then have to be discarded. This means that the costs of production are increased.

On the other hand, CNC machines are exact. They do not commit errors, which can lead to material wastage, and they use almost the entire material. This leaves little room for wastage, making the production process more efficient.…